READ MORE

READ MOREPneumatic Actuators

The pneumatic actuator has simple structure and high reliability. The response time of pneumatic actuators can often reach the millisecond level, which has a faster response speed than electric actuators, which is very advantageous in industrial automation and control applications where fast response is required. The working principle of the pneumatic actuator is to use the force of gas compression and expansion to drive the piston movement, and the material is usually metal, which makes the pneumatic actuator excellent in mechanical wear, and the service life can reach several years or even more than ten years. Pneumatic actuators are suitable for a variety of industrial fields, such as chemical, petroleum, pharmaceutical and food, especially for small and medium power mechanical equipment and automatic control systems.

READ MORE

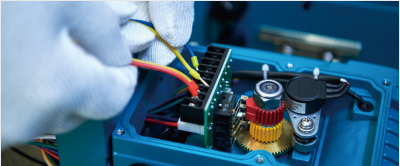

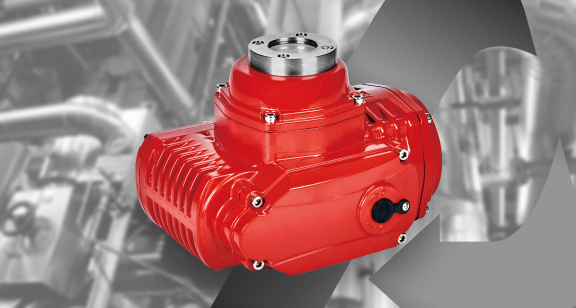

READ MOREElectric actuator

Electric actuators can achieve remote control and automatic control, improve production efficiency and product quality. Valve opening and closing speed is fast and can adapt to high frequency switching and emergency cutting requirements. Valve adjustment accuracy is high, which can be applied to precision adjustment control and flow measurement. Valve seal is good, can be applied to high temperature, high pressure, corrosive media and other harsh environment. Simple structure, easy maintenance, high reliability, long service life.

READ MORE

READ MOREPneumatic Valves

Pneumatic valve adopts compact design, simple structure, easy installation and maintenance. It can be operated by pneumatic actuator, easy operation, remote control and automatic control can be easily achieved. The use of high-quality materials and manufacturing technology with high reliability and stability can adapt to a variety of harsh working environments. The use of advanced sealing technology can ensure good sealing performance and prevent medium leakage. Pneumatic valves are made of corrosion-resistant materials and can adapt to various corrosive media.

READ MORE

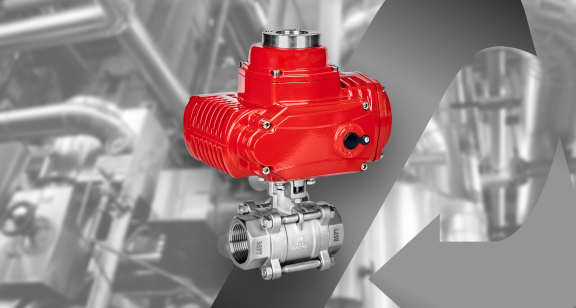

READ MOREElectric Valves

The electric valve is electrically driven, which can achieve fast switching, and can greatly improve efficiency for some occasions that require frequent switching. It is usually equipped with a variety of safety protection measures, such as overload protection, overvoltage protection, undervoltage protection, etc., which can ensure that the valve automatically stops in abnormal circumstances to ensure equipment and personal safety. The parts of the electric valve have been carefully designed and manufactured, using high-quality materials and advanced processing technology to ensure the reliability and service life of the valve. Electric valves are usually equipped with a programmable controller, which can be programmed and controlled according to the needs of users to achieve intelligent control and remote monitoring.

READ MORE

READ MOREPneumatic Pinch Valve

The structure is novel and simple, the inner diameter of the rubber sleeve is the same as that of the pipe, and the local resistance loss is small.There is no sealing point, the control medium space and the valve channel are completely isolated, and no internal and external leakage will occur. Relying on rubber sleeve deformation to achieve opening and closing, even if the fluid contains solid particles or fiber impurities will not block, can be completely and quickly closed its package. Simple structure, only three parts, can replace large volume, complex structure of the valve, especially suitable for explosion-proof requirements of the occasion.

READ MORE

READ MOREPowder Butterfly Valve

Single flanged valves with top flanges and flanged components apply to connecting to flexible bushings.Double flanged valve, top and bottom of the same flange. The gravity casting valve body is stronger than the pressure casting valve body. The rotary valve plate is made of polymer material, resistant to wear. Fewer components, light weight, easy to handle.

Application

Petrochemical

Autorun valves for the chemical industry are designed to provide safety, reliability and high performance for the most demanding applications.

Pharmaceutical and Biotechnology

‘Pharmaceutical and biotechnology companies face competitive pressures to improve efficiency, reduce costs and increase flexibility. Eurotronics works with global leaders to solve industry challenges with valves, controllers and accessories.’

Power

Autorun, with over 20 years of experience, provides reliable valves, actuators and accessories for mission-critical power plants.

Mining and Metallurgy

‘Autorun combination of actuators and controls for butterfly, ball, knife gate, slurry and check valves. are widely used in mining and metallurgy worldwide, providing the industry with stable and reliable valve solutions.’

Food and Beverage

‘Autorun valve products are used in a number of important sectors, including the health services food and beverage industry, antimicrobial treatment, drinking water treatment and brewing.’

Water Treatment

Autorun is a manufacturer of quality valves, actuators and fittings trusted for the sustainable management of water and wastewater treatment plants around the world.

Contact Us

Your Name

Telephone

Company

Address

Message